Pioneering material solutions for energy and telecommunications

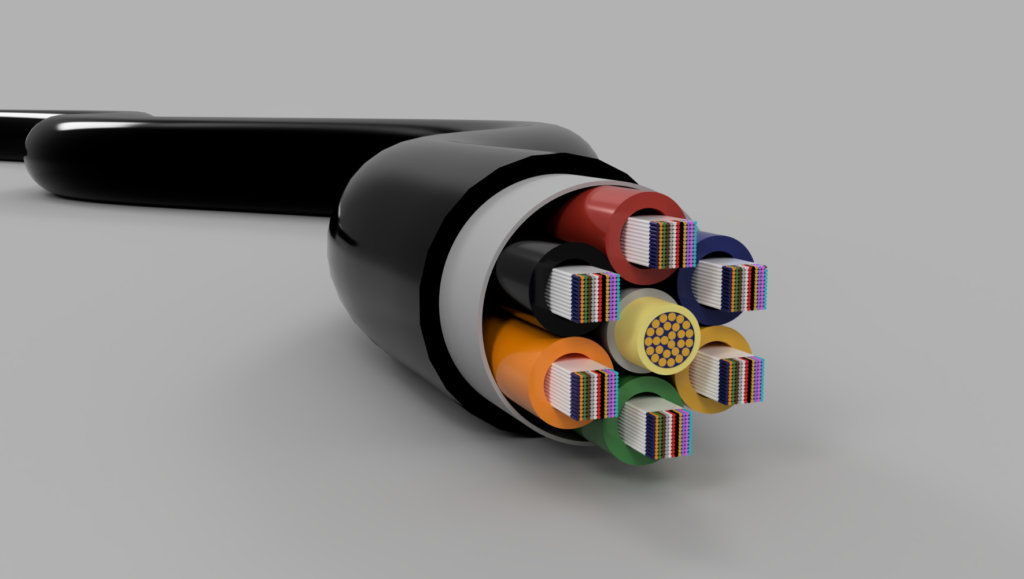

Covestro, a leading global supplier of high-performance materials, will present advanced material solutions tailored to the energy and telecommunications sectors at the wire trade fair in Düsseldorf from April 15 to 19, 2024. Under the motto “Connect with Us: Optical Fiber and Cable Solutions”, the company is presenting a broad portfolio from four business units with products that complement each other very well.

The wire and cable industry plays a central role in the global networking of society, especially in the transmission of energy and data. Reliability and efficiency are of paramount importance for these products. That is why Covestro supports its customers with durable, high-performance and more sustainable material solutions.

The materials presented include:

• Coatings, inks and matrix: Covestro’s innovative coatings, inks and matrix materials are designed to provide exceptional protection and performance in various applications in the energy and telecommunications industries. With more than 40 years of industry experience in fiber and cable materials, Covestro offers improved design capability, field deployability, reliable performance, ultra-fast curing and excellent protection against attenuation and micro-bending.

• Polycarbonates: Covestro’s polycarbonate materials are characterized by excellent strength, transparency and versatility, making them well-suited for a wide range of energy and telecommunications applications. From optical fibers to electrical housings, Covestro’s polycarbonates ensure dimensional stability and impact resistance over a wide temperature range.

• Thermoplastic polyurethanes: Covestro’s thermoplastic polyurethane (TPU) solutions combine flexibility, toughness and chemical resistance, making them ideal for the protection of flame-retardant cables in various energy and telecommunications applications.

• Elastomers: Covestro’s elastomer materials are tailored for exceptional durability and strong resistance against wave and tidal action for energy subsea applications. They offer thermal stability, impact resistance and reliable protection against flex fatigue and hydrolysis. They are durable and reduce maintenance in the offshore wind industry.